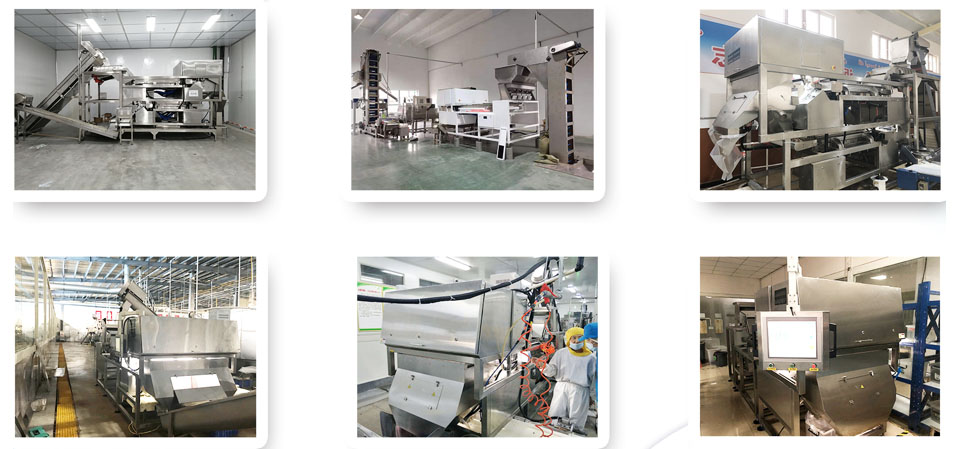

Peanut Groundnut Optical Color Sorter Equipment

The primary application of Techik Optical Peanut Groundnut Color Sorter Equipment is within the agriculture and food processing industries. It is used to sort peanuts based on their color and appearance to ensure product quality, remove defects, and enhance the overall visual appeal of the final product.

The sorting performance of Techik Optical Peanut Groundnut Color Sorter Equipment:

Here are some specific applications of Peanut Groundnut Color Sorters:

Peanut Processing Plants: Peanut Groundnut Color Sorters are commonly used in processing plants where raw peanuts are cleaned, sorted, and prepared for various products. This includes applications in peanut butter production, snack manufacturing, and other food products that use peanuts as an ingredient.

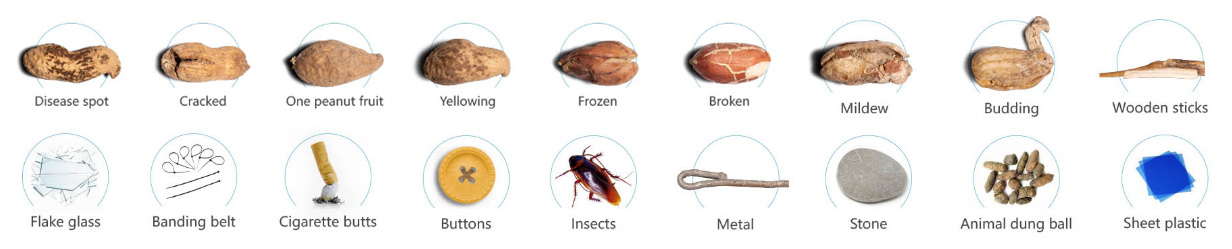

Quality Control: Peanut Groundnut Color Sorters play a crucial role in quality control processes. They help identify and remove discolored, damaged, or defective peanuts, ensuring that only high-quality peanuts meet the required standards for packaging and distribution.

Food Safety: By removing foreign materials, contaminants, and potentially harmful substances, Peanut Groundnut Color Sorters contribute to food safety. They help prevent the presence of allergens, stones, shells, and other undesirable elements in the final product.

Uniformity in Appearance: For products like peanut snacks or peanut butter, uniformity in color and appearance is important for consumer satisfaction. Color sorters help achieve consistent appearance, contributing to a more visually appealing end product.

Export and Packaging: In the context of exporting peanuts, color sorting ensures that the product meets the quality standards and visual expectations of international markets. It also helps enhance the market value of the exported peanuts.

Minimizing Waste: By removing defective peanuts and contaminants, Peanut Color Sorters help minimize waste and maximize the utilization of available raw materials. This is crucial for cost efficiency and sustainability.

Custom Sorting: Some manufacturers might require custom sorting criteria to meet specific market demands or quality standards. Peanut Color Sorters can be programmed to sort based on precise color ranges or other visual characteristics as needed.

Process Optimization: Peanut Color Sorters can be integrated into larger processing lines to optimize subsequent processes. For example, they can sort peanuts based on their intended use, such as separating peanuts for roasting from those destined for grinding into peanut butter.

Overall, the application of a Peanut Color Sorter contributes to product quality, food safety, production efficiency, and customer satisfaction within the peanut processing industry.