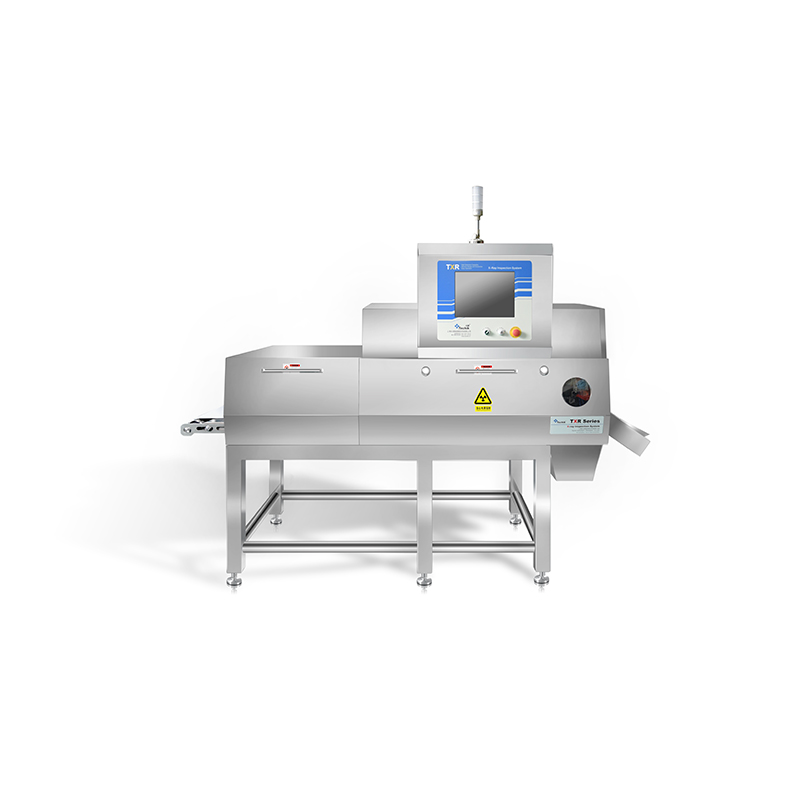

X-ray Inspection System for Bulk Products

The application of X-ray Inspection Systems for Bulk Products in the agricultural industry is crucial for ensuring the safety, quality, and compliance of various agricultural products.

X-ray Inspection Systems play a vital role in safeguarding the quality and safety of agricultural products. By identifying contaminants, ensuring packaging integrity, and providing a non-destructive means of assessing internal quality, these systems contribute to the overall quality control processes in the agricultural industry.

Quality Control of Grains and Seeds:

Contaminant Detection: X-ray systems can identify foreign objects, such as stones, glass, or metal, in bulk quantities of grains and seeds, preventing these contaminants from reaching the consumer.

Nuts and Dried Fruits Inspection:

Detecting Shell Fragments: X-ray inspection is effective in identifying shell fragments or foreign materials in nuts, ensuring that the final product is safe for consumption.

Dairy Products Inspection:

Checking Packaging Integrity: X-ray systems can inspect the integrity of packaging for dairy products, such as cheese or butter, ensuring that there are no defects or contaminants that could compromise the product.

Processed Foods and Snacks:

Contaminant Identification: X-ray inspection helps identify contaminants like bones, metal, or other foreign materials in processed foods and snacks, ensuring product safety.

Fresh Produce Inspection:

Internal Quality Check: X-ray systems can be used to assess the internal quality of fruits and vegetables, detecting internal defects, bruises, or foreign materials without compromising the integrity of the produce.

Bulk Meat and Poultry Inspection:

Bone and Metal Detection: X-ray systems are valuable for detecting bones and metal fragments in bulk quantities of meat and poultry, ensuring consumer safety and compliance with food safety regulations.

Bulk Tobacco Inspection:

Detecting Non-Tobacco Materials: In the case of bulk tobacco processing, X-ray inspection can identify non-tobacco materials, ensuring the purity of the final product.

Compliance with Food Safety Standards:

Ensuring Regulatory Compliance: X-ray Inspection Systems aid in compliance with strict food safety regulations by identifying and preventing the distribution of products with contaminants or defects.

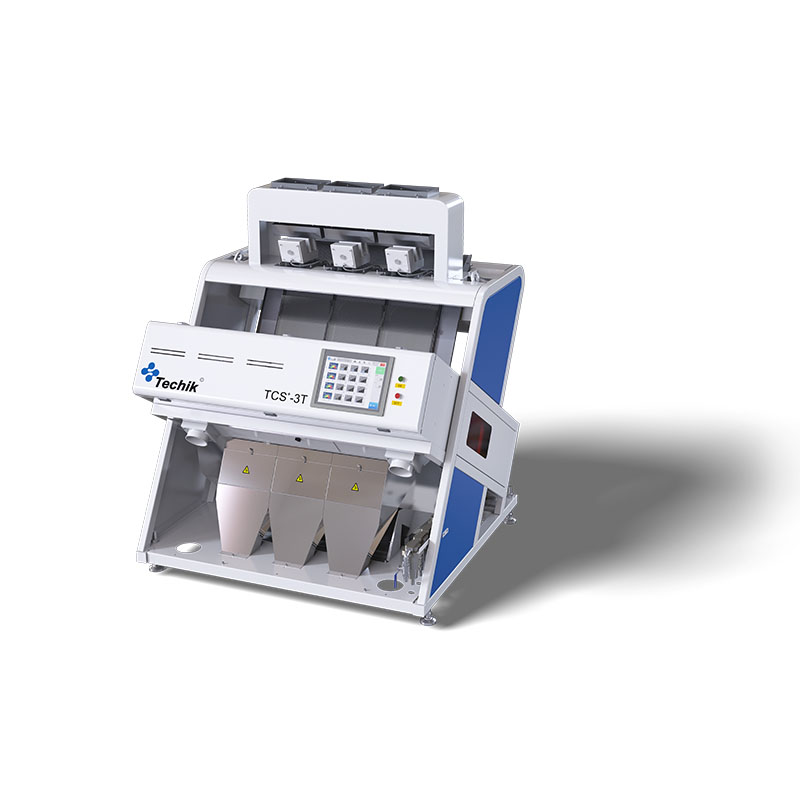

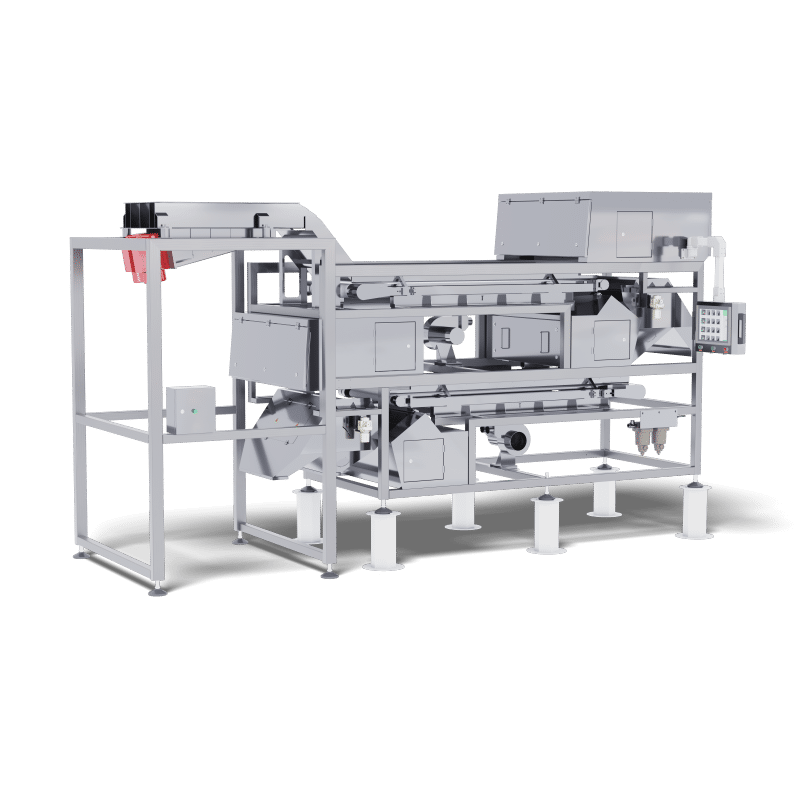

Sorting and Grading:

Automated Sorting: X-ray systems integrated with sorting mechanisms can automatically separate products based on their internal characteristics, allowing for efficient grading and sorting.

Non-Destructive Inspection:

X-ray inspection is non-destructive, allowing for thorough examination of the internal features of bulk products without compromising their integrity. This is crucial for quality control in industries where the structural integrity of the product is essential.

Quality Assurance:

The system helps in identifying defects, contaminants, or irregularities within the bulk products. This is vital for ensuring the quality and safety of the end product.

Contaminant Detection:

X-ray inspection can identify contaminants such as metal, glass, stone, or other dense materials that may be present in bulk products. This is especially important in the food industry to prevent contamination and ensure compliance with safety standards.

Density and Composition Analysis:

X-ray systems can provide information about the density and composition of materials within bulk products. This is useful for verifying the composition of mixtures or detecting variations in product density.

Foreign Object Detection:

It is effective in detecting foreign objects within bulk materials, which can include items such as plastic, rubber, or other materials that may have unintentionally entered the production process.

Packaging Inspection:

X-ray systems can also inspect the integrity of packaging materials, ensuring that seals are intact and that there are no defects that could compromise the product during transport or storage.